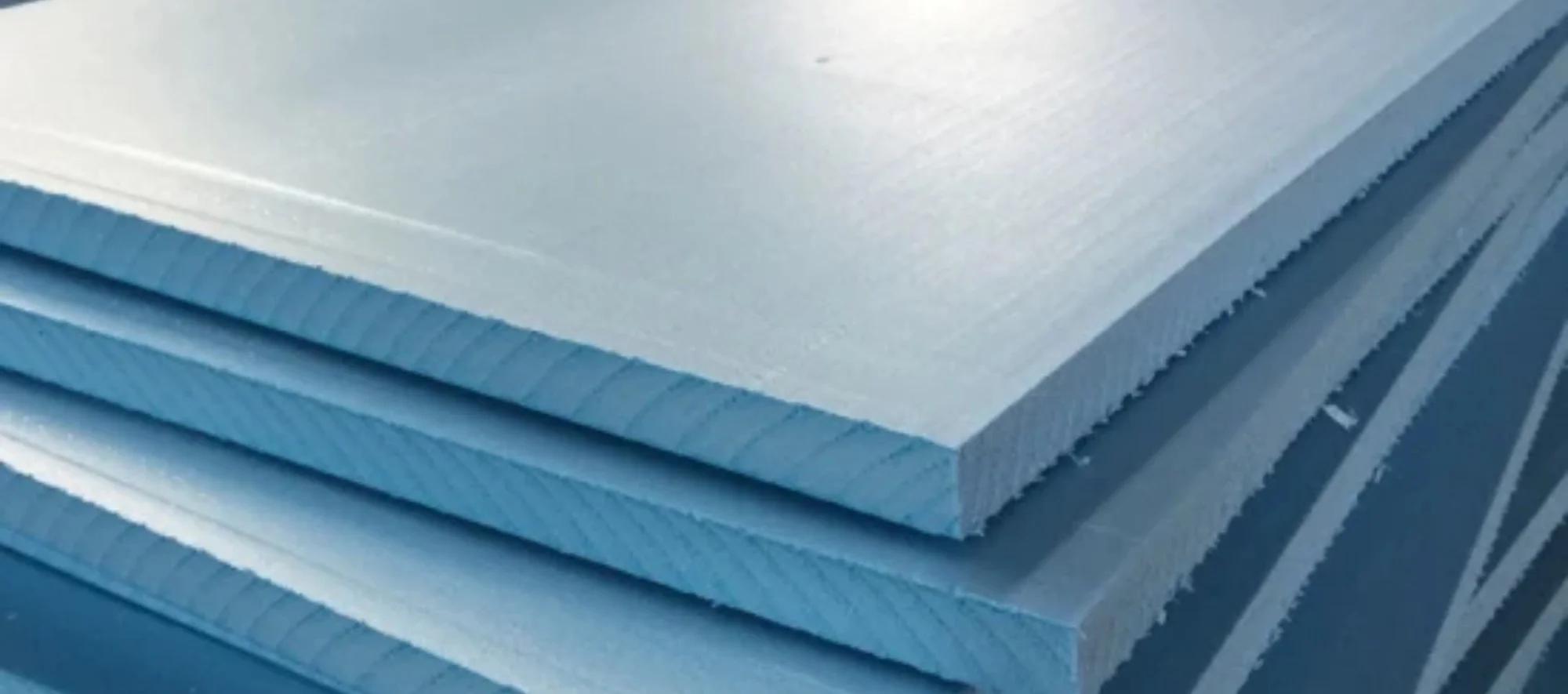

Premium Foam Board Manufacturers for Superior Insulation and Versatility

Foam boards have become essential components in construction, packaging, and industrial applications due to their lightweight structure, thermal insulation, and durability. Partnering with reliable foam board manufacturers ensures consistent quality and performance for any project. Whether for commercial, residential, or industrial purposes, sourcing from a trusted manufacturer guarantees materials that meet your exact specifications.

Composite Box is a leading name among foam board manufacturers, providing high-quality rigid foam boards that cater to a wide range of applications and industries.

Understanding Foam Boards

Foam boards are rigid panels typically made from polystyrene, polyurethane, or polyisocyanurate. They are designed with a closed-cell structure, offering excellent insulation properties while remaining lightweight. This combination of features makes them suitable for many uses, from building insulation to packaging fragile items.

Key Features of Foam Boards:

- Lightweight yet strong, ideal for easy handling.

- High thermal insulation to maintain energy efficiency.

- Moisture resistance for long-lasting durability.

- Versatility for multiple industrial applications.

Key Applications of Foam Boards

1. Building and Construction

Foam boards are widely used in walls, floors, and roofs to improve thermal insulation, reducing heating and cooling costs.

2. Signage and Advertising

With a smooth surface and lightweight design, foam boards are ideal for displays, trade show signs, and retail advertisements.

3. Packaging Solutions

Foam boards provide protective cushioning for delicate products, ensuring safe transportation and reducing damage risks.

4. Transportation and Refrigeration

Used in refrigerated truck bodies and shipping containers, foam boards help maintain controlled temperatures for perishable goods.

Advantages of Working with Professional Foam Board Manufacturers

Selecting experienced foam board manufacturers brings numerous benefits:

Consistency and Quality

Professional manufacturers maintain strict quality control to ensure uniform thickness, density, and performance.

Customized Solutions

Manufacturers like Composite Box can create foam boards in various sizes, densities, and finishes to suit specific requirements.

Technical Expertise

Suppliers provide guidance on the most suitable foam type and specifications for your project needs.

Reliable Supply

Trusted manufacturers ensure steady production and timely delivery, even for bulk orders.

Why Choose Composite Box as Your Foam Board Manufacturer

Composite Box stands out among foam board manufacturers for quality, customization, and reliability.

Superior Materials

Premium raw materials ensure excellent insulation, strength, and durability.

Advanced Production Techniques

State-of-the-art equipment ensures precise dimensions and consistent quality.

Custom Options

Boards can be tailored in thickness, density, and surface finish to meet unique project requirements.

Global Reach

Efficient logistics allow timely delivery of foam boards worldwide.

Tips for Maintaining Foam Boards

Proper Storage

Keep foam boards in dry, shaded areas to prevent moisture absorption and UV damage.

Careful Handling

Avoid bending or exerting excessive pressure to prevent structural damage.

Cleaning

Use a soft cloth and mild detergent to maintain a clean surface without causing scratches.

Selecting the Right Foam Board Manufacturer

When choosing a foam board manufacturer, consider the following:

- Material type suitable for your application (EPS, XPS, polyurethane).

- Product range to cover all your project needs.

- Compliance with industry standards for safety and performance.

- Cost-effectiveness balanced with quality.

- Customer support and technical guidance.

Conclusion

Reliable foam board manufacturers play a critical role in delivering high-quality, durable, and versatile materials for construction, packaging, and industrial applications. By choosing Composite Box, businesses gain access to premium rigid foam boards, customized solutions, and dependable supply—ensuring projects are completed efficiently and to the highest standards.

This partnership guarantees superior performance, cost efficiency, and peace of mind for any foam board application.

Post Comment